Mail us on corrosionprotectioncouncil@gmail.com

Call us on +91 22 2222 3333

Objectives

Why CPCI?

Main Objective of CPCI is to develop and implement innovative strategies and technologies aimed at achieving corrosion-free construction practices, thereby ensuring the safety, sustainability and well-being of individuals and communities for significant Infrastructure Projects and to create awareness about problems associated with Corrosion and the ill-effects of the same.

Corrosion of Rebar

Reinforcement Steel embedded in cement concrete is believed to be safe from corrosion for its life time. Corrosion is a natural phenomenon and corrosion of steel is most common. Therefore, while we plan infrastructures along the length and breadth of a tropical country like India with a vast coast line, we need a proper, time tested and an effective corrosion protection strategy in place. This would enable the coming generation to use this infrastructure as a launching pad for further development.

There are many methods tried and tested all over the world to combat the menace of rebar corrosion. They are as follows:

- High performance concrete

- Corrosion inhibitors

- Coatings on concrete surface

- Cathodic protection

- Corrosion resistant steel bars

- Coatings on rebars

As the problem occurs on the steel bar surface, the most effective way is to attend the problem where it occurs. Therefore, more importance is given to coatings on rebar. Types of coatings which are commercially available in India are;

- Galvanising

- Cement Polymer Composite Coating

- Various Polymer based brush applied Coatings

- Fusion Bonded Epoxy Coating

Galvanising:

Galvanising is one of the oldest methods of protecting steel against corrosion. Normally zinc is applied to the bar in a factory either by hot dipping or by electro plating. In the event of corrosion the zinc would act as a sacrificial anode. Galvanising can offer protection to steel rebar against the effects of carbonation. It can also resist chloride attacks perhaps better than a normal black rebar. However, the biggest drawbacks are the potential difference of coated and uncoated areas and its inability to provide long term protection in moist and chloride environments such as marine or coastal areas.

Cement Polymer Composite Coating:

Cement Polymer Composite Coating system for corrosion protection of reinforcing steel (CPCC) is one of the latest introduced system by Central Electrochemical Research Institute, Karaikudi. This has not been tested for its performance on a long duration by anybody.

The coating comprises of three stages, Surface preparation by sand blasting followed by a primer coat and finally a sealing coat where Ordinary Portland Cement is used as a pigment. The method of application is manual except for sand blasting. Although this method has been accepted on some government projects, it is not widely proven and is best reserved for experimental use.

Polymer Based Liquid Coatings:

These coating is Brush-applied at site with minimal surface preparation and are not found to contribute much towards prevention of corrosion. It has a polarisation resistance of less than 100 ohms per sq. cm. Their limitations are the loss of adhesion and its poor performance in highly alkaline environment.

Fusion Bonded Epoxy Coatings:

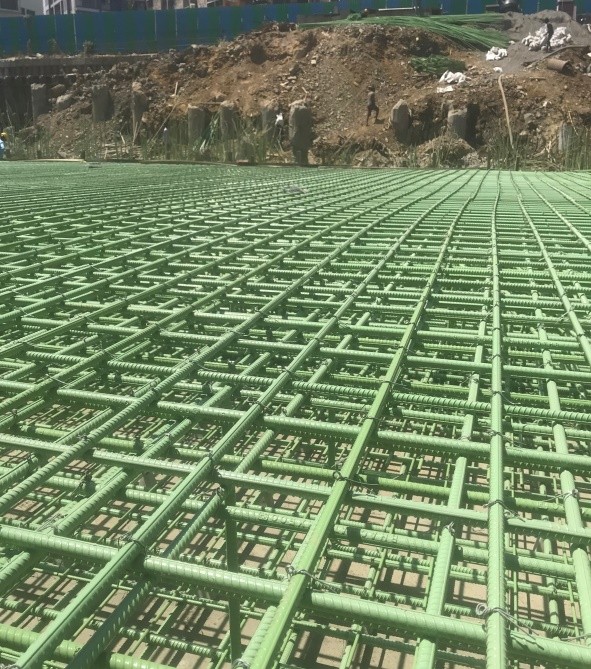

One of the most widely used and advanced method in India to combat rebar corrosion is to coat rebar with Fusion Bonded Epoxy. The Fusion Bonded Epoxy coating is an Electrostatic application of epoxy powder on heated steel at pre-set temperature level. The powder, when in contact with the hot bar, it melts, flows, gels and cures to a well-adhered continuous corrosion resistant protective coating.

The steel bars are machine-blasted; then heated through the induction heating at pre-set temperature levels. Hot bars are then fed to the coating booth, where the epoxy powder is applied electrostatically. The bars are cured and force-cooled to enable handling and testing.

Fusion Bonded Epoxy is ideally suited for protective coating on the complex surface configuration of a reinforcing steel bar. Electrostatic deposition, combined with controlled melt and flow can attain uniform coating to desired specifications. The flexibility of the coating and better abrasion resistance enable the Fusion Bonded Epoxy coated rebars to be as easy to handle as the original bars, with moderate additional care.